The variation in wire color codes for 4-wire O2 sensors across manufacturers like Toyota, Honda, and Chevrolet presents a significant challenge in identifying the correct wiring configuration. This variability underscores the need for a universal approach to deciphering wire functions without solely relying on color-coding.

Identifying Signal-Wire Polarity Without Color Codes

Fortunately, determining the signal-wire polarity of a 4-wire O2 sensor does not hinge on wire colors. A two-step testing process, employing a multimeter and a premix flame source, such as a blowtorch or gas stove, can elucidate each wire’s function, provided the O2 sensor is operational:

- Heater Wires Identification: Initially, use a multimeter in resistance mode to discern the heater wires, which exhibit a resistance reading typically between 4-6 Ω. These wires heat the O2 sensor, ensuring it reaches operating temperature. Their identification is crucial as they show either an open circuit or infinite resistance for non-heater wires;

- Sensor Signal Polarity Test: This test involves setting the multimeter to voltage mode and heating the sensor’s tip. Observing the voltage reading, which should fall within the 0-1 V range, helps identify the signal and ground wires based on the voltage polarity indicated by the multimeter.

Universal O2 Sensor: Compatibility and Installation

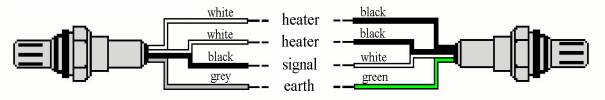

“Universal” O2 sensors are designed to cater to a broad spectrum of vehicles by forgoing specific connector plugs in favor of short trailing wires. This design choice necessitates cutting and joining wires from the original sensor to the new one, a process that emphasizes the importance of correctly identifying wire functions to ensure proper sensor operation.

Wire Color Scheme: A Comparative Overview

Given the diversity of color schemes across different car and sensor manufacturers, a comparative analysis becomes invaluable. While 3-wire sensors generally follow two main color schemes for heater and sensor wires, 4-wire sensors introduce an additional ground wire, complicating the matching process. Nevertheless, understanding the functional role of each wire allows for accurate connections, irrespective of color discrepancies.

Advanced Techniques for O2 Sensor Identification

In the realm of automotive diagnostics and repair, accurately identifying the wiring of O2 sensors without relying on color codes is a skill that significantly enhances the efficiency of installing universal sensors. Beyond the basic identification tests involving resistance and voltage measurements, advanced techniques such as waveform analysis and sensor response testing offer deeper insights into sensor functionality. Waveform analysis, conducted with an oscilloscope, allows technicians to observe the sensor’s output in real-time under various engine conditions, providing a dynamic view of its performance and health. This method can pinpoint issues with sensor responsiveness, signal stability, and the presence of any electrical interference that could skew readings.

Furthermore, sensor response testing, which evaluates the sensor’s ability to react to changes in exhaust gas composition, can be conducted through controlled enrichment and leaning of the air-fuel mixture. This test assesses the sensor’s operational range and speed of response, critical factors in its ability to provide accurate feedback for engine control adjustments. These advanced diagnostic techniques not only aid in the precise installation of universal O2 sensors but also contribute to the overall understanding of engine performance and emission control systems. By leveraging these methods, technicians can ensure optimal sensor function and vehicle performance, underscoring the importance of comprehensive diagnostics in modern automotive maintenance.

The Evolution of O2 Sensors and Environmental Impact

The development of O2 sensors represents a pivotal advancement in automotive technology, with profound implications for vehicle efficiency and environmental protection. Initially introduced in the late 1970s to meet emerging emission regulations, O2 sensors have evolved from simple binary devices to complex wideband sensors capable of providing precise air-fuel ratio information across a broad range of conditions. This evolution has enabled significant improvements in engine management systems, allowing for finer control over combustion processes, reduced emissions, and improved fuel economy.

Moreover, the role of O2 sensors in environmental protection cannot be overstated. By ensuring optimal combustion, these sensors directly contribute to lowering the output of harmful pollutants such as nitrogen oxides, carbon monoxide, and unburned hydrocarbons. The advancements in sensor technology, including the transition to wideband sensors and the integration of temperature sensors for faster light-off times, reflect a continued commitment to environmental stewardship through automotive innovation. As regulations become increasingly stringent and the automotive industry moves towards electrification, the lessons learned from the development and implementation of O2 sensors will undoubtedly influence future approaches to emission control and engine efficiency, reinforcing the sensor’s legacy as a cornerstone of automotive environmental technology.

Comparative Table: O2 Sensor Testing Techniques

| Testing Technique | Description | Advantages | Disadvantages |

|---|---|---|---|

| Resistance Measurement | Identifies heater wires by measuring resistance. | Simple and quick; requires only a multimeter. | Does not assess sensor functionality. |

| Voltage Measurement | Determines signal wire polarity by observing voltage response to heat. | Provides direct insight into signal wire identification. | Requires sensor to be heated; may not indicate sensor health. |

| Waveform Analysis | Uses an oscilloscope to observe the sensor’s output waveform. | Offers detailed view of sensor performance and health. | Requires specialized equipment and technical knowledge. |

| Response Testing | Evaluates sensor’s responsiveness to changes in air-fuel mixture. | Tests operational range and speed; can indicate sensor health. | More complex setup; requires controlled manipulation of air-fuel mixture. |

Video Guide

To answer all your questions, we have prepared a video for you. Enjoy watching it!

Conclusion

The challenge of wiring a universal O2 sensor amidst the confusion of varying color codes can be surmounted through a methodical testing approach. By focusing on the functionality of each wire rather than its color, vehicle owners can confidently install universal O2 sensors, ensuring optimal vehicle performance and emissions control. This pragmatic strategy not only demystifies the installation process but also enhances the accessibility of performance maintenance for a wide range of vehicles, bridging the gap between complex color codes and straightforward sensor functionality.